Dryers

Heat Recovery Drum Dryer

Features

- Katsuragi’s Heat Recovery Drum Dryer was developed to reduce the facility cost and running cost. Generally exhaust air (vapor) from the dryer is discharged into the atmosphere. However, in this drum dryer, from such exhaust air, heat is recovered through the scrubber condenser and heat recovery system. With such recovered heat, pre-concentration is carried out. We could adopt a small-sized drum dryer by carrying out this pre-concentration, and as a result, succeeded in reducing the steam consumption. (Approx. 40% reduction compared to the conventional company products)

For the volume reduction of industrial waste!

- Energy saving Reduction of CO2 emissions

- Low-priced and compact A low-priced and compact system is realized by packaging a pre-concentrator in the dryer.

- Odor reduction Odor is also reduced by reducing the volume of exhaust emissions.

- Reduction of CO2 emissions Fuel consumption of the boiler is reduced by reducing the steam consumption, which results in the CO2 reduction.

Comparison of operating cost between the drum dryer and heat recovery drum dryer

1. Specifications

- Type of liquid treated: Salt wastewater

- Treated liquid volume: 6 m3/day (salt concentration: 5%)

- Concentrated liquid volume in pre-concentration: 4 m3/day (salt concentration: 7.5%)

- Amount of dried materials: 300 kg/day (NaCl)

2. Utility and running cost

| Drum dryer | Heat recovery drum dryer | |||

|---|---|---|---|---|

| Utility | Amount used | Steam (kg/h) | 365 | 212 |

| Electricity (kW) | 11.6 | 15.6 | ||

| Cost (yen/year) | Steam | 9,198,000 | 5,342,400 | |

| Electricity | 993,888 | 1,336,608 | ||

| Total | 10,191,888 | 6,679,008 |

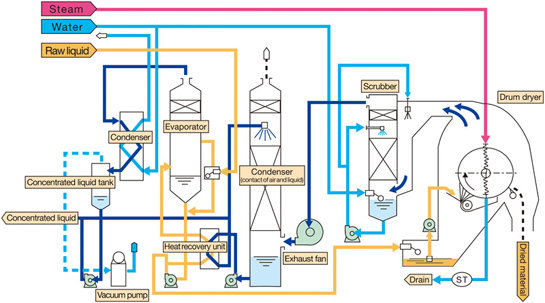

Flow sheet

Standard specifications

| Model | Treated volume | Main unit specifications of dryer | System’s outline dimensions (mm) | Utility | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Drum size | Surface area | Power | Steam | Electricity | ||||||

| kg/h | Diameter | Length | m2 | kW | W | L | H | kg/h | kW/h | |

| HRD-S-0610 | ~90 | 600 | 1,000 | 1.8 | 1.5 | 1,800 | 4,100 | 3,200 | 80 | 6.0 |

| HRD-S-0815 | ~180 | 800 | 1,500 | 3.7 | 2.2 | 2,200 | 5,000 | 3,500 | 160 | 8.7 |

| HRD-S-1020 | ~285 | 1,000 | 2,000 | 6.2 | 5.5 | 2,600 | 6,500 | 3,800 | 255 | 15.6 |

| HRD-S-1025 | ~345 | 1,000 | 2,500 | 7.8 | 5.5 | 2,600 | 7,000 | 3,800 | 310 | 16.3 |

| HRD-S-1520 | ~420 | 1,500 | 2,000 | 9.4 | 7.5 | 2,800 | 6,700 | 4,000 | 375 | 22.7 |